Services

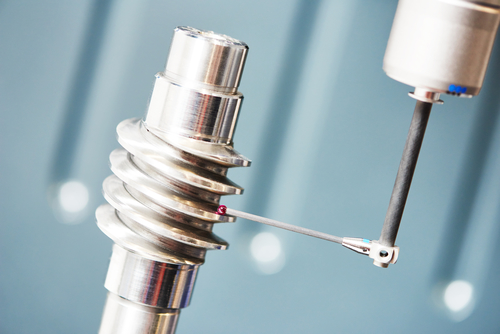

As part of a fully equipped quality lab, Precise Dimensional Inspection utilizes multiple systems to provide accurate, precise measurements. These measurements include third party inspection (in-process or final), first article inspections, capability studies, and quality engineering. CMM inspection is commonplace amongst precision machine shops. Very few shops, however, have the expertise and technology to offer reliable third party inspection. CMMs inspect part dimensions for location and/or accuracy. Parts can be fixtured or rotated to inspect dimensions that may be difficult to reach.

Professional Layout-Metrology Services

PDI offers state-of-the-art professional layout metrology services, including dimensional inspection, quality certifications, and programming. As an ISO/IEC 17025 accredited laboratory, PDI adheres to the highest standards. Whether you seek First Article Inspection(FIA) in accordance with AS9100 verification or other assistance, PDI offers best-in-class and customizable metrology support. We employ the most accurate technologies and equipment for your manufacturing and design measurement needs.

Our dynamic temperature controlled and humidity monitored lab houses the best measurement equipment from the best OEMs. We feature both touch and touchless data collection methods that suit all industries from automotive, medical, aerospace, manufacturing and others.

Trained in the art of dimensional metrology and stewards of the study of measurement and B/P interpretation we have a passion for providing you quick and accurate data and analysis. Most of our customers are engineers that tend to appreciate communicating with other engineers and experienced hands on approach to their projects. Not only do we know how to properly operate the equipment, we understand underlying measurement based considerations and implications of your print dimensions. PDI is trained in each data collection technology and software that we use. We understand the strengths and weaknesses of each type of equipment and are able to intelligently confirm to you which is best for your project. Ensuring your project will have the benefit of a skilled tradesman in all metrology based areas.

Services provided

Inspection Of:

- Castings

- Stampings

- Production Tooling

- Gage Fixtures

- Molds

- Plastics

- Springs

Calibration of:

- Plug gages

- Calipers

- Micrometers

- Ring Gages

Dimensional Inspection Services: More than Just Measurement

Dimensional Inspection, also called Dimensional Metrology, assesses the geometric characteristics of machined parts and products to verify their compliance with design specifications. Dimensional inspection services ensure the accuracy of the product features that can affect reliability and functionality. With the ever-increasing influx of automation in the manufacturing industry, the process of prioritizing accurate measurements is needed now more than ever to ensure that products are not only being manufactured on time, but that production is repeatedly accurate. In this continuous, rapid-paced environment, time is becoming an even more valuable commodity, making the time-saving information provided by dimensional inspection an increasing necessity.

At PDI, simplified, dimensional inspection can be seen as the process for comparing what an object actually is to what it is supposed to be, and uses quantifiable values to measure virtually any physical characteristics such as:

- Length, width, and height.

- Angles and perpendicularity.

- Roundness, flatness, and other geometric characteristics.

- Position.

- Shape profiles.

- Surface characteristics.

- Edge sharpness.

- Thickness and uniformity.

PPAP Submission Services

Automotive suppliers are required to go through a Production Part Approval Process, or PPAP submission, if introducing a new or modified part into the production process. PDI ensures that the client’s requirements are understood, the product meets those requirements, the process is capable of producing a conforming product, and that the product control plan along with the quality management system will prevent non-conforming parts from reaching the client.

PPAP submission packets can save automotive manufactures time and money when completed correctly. However, failure to correctly and thoroughly complete the PPAP can result in lost time and money through failures and recalls.

PPAP completion is time consuming, and requires appropriately trained staff and equipment. PDI, is accredited and experienced in supplying the necessary dimensional verification for the PPAP packet. Our lab is equipped with highly accurate technology for metrological inspection.

- Laser Micrometer

- Coordinate Measurement Machine

- Video inspection systems

- Optical Comparators

- Contour measurement equipment

Our staff provide inspections that are highly accurate, very thorough and as efficient as possible, so you get your information back in a timely manner. Let our team help you complete your next PPAP. For more information about our PPAP submission services or to receive a quote, fill out the form using the button below and discuss your project with a PDI team member.

Product Inspections, Including:

- PPAP Inspections

- 3rd Party Determination

- Fixture Inspection

- 1st Article Inspection

- Impartial Evaluations

- GD&T Interpretation